Robotics Control Business Products and Services related to Robot Control Business

MISSIONRobot Control Business’s Domain and Mission

We provide distinctive, high value-added products by making full use of motor control technology and various control technologies accumulated over 40 years since foundation.

Our AdvantageTIETECH’s strength

TIETECH’s strengths lie in its technical expertise in motor control and ability to respond to customer needs and applications.

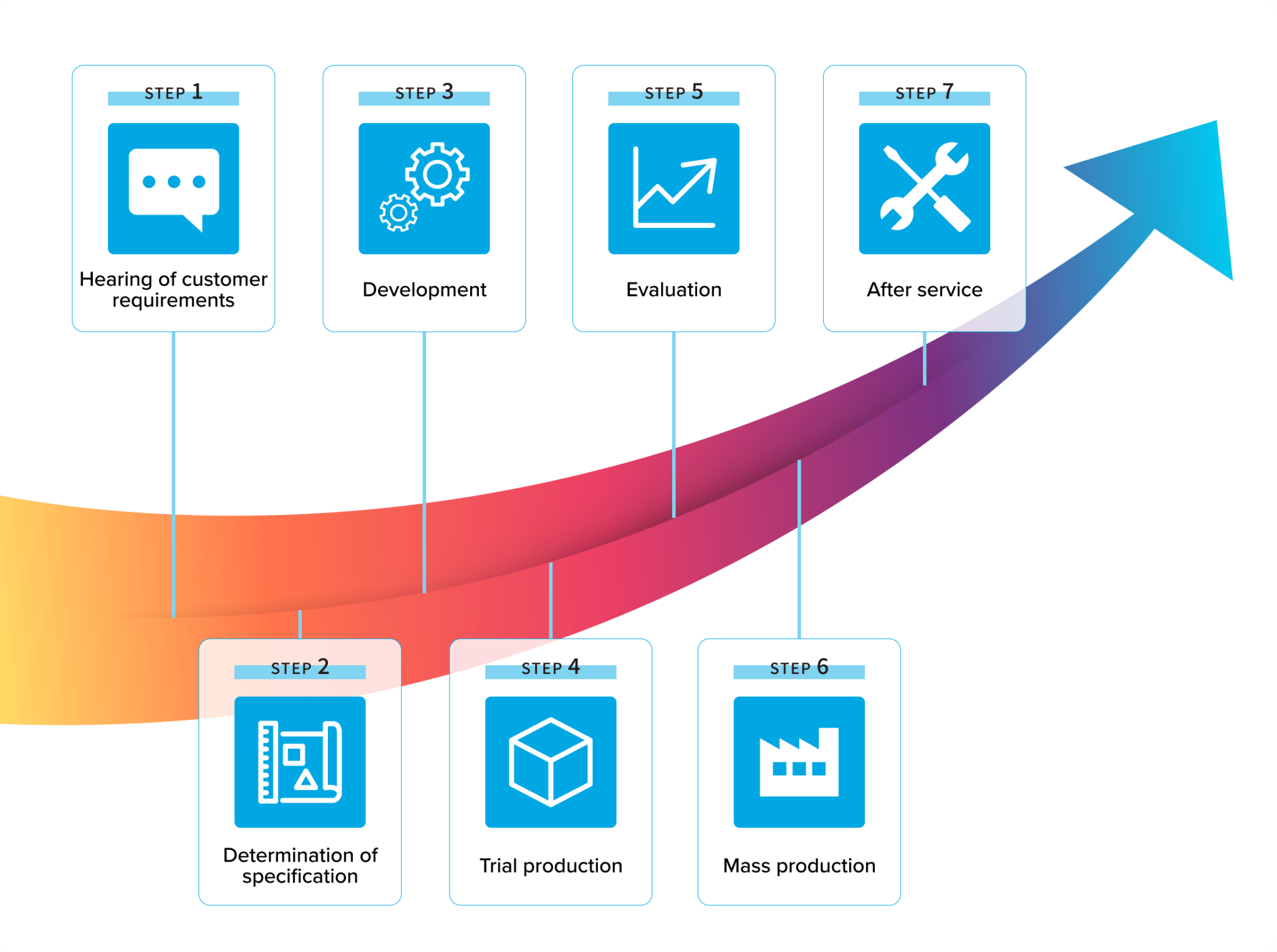

01 One-stop solution

We can provide integrated services in-house, from product development to manufacturing.

02 Product development according to needs

Product development according to customer requirements

Customization services are also available

TIETECH’s drivers can rotate any motor

With our servo driver technology cultivated over 40 years, we can develop drivers optimized for any motor.

Available in sizes that fit into existing equipment

We respond to increasing needs for smaller and lighter equipment.

We also respond to inquiries such as “The existing servo driver is too large to fit into the equipment.

Fine mechanical tuning

We can help you solve the compatibility problem between the robot’s mechanical part and the driver.

We can develop drivers optimized for mechanical parts based on our many years of trust and experience.

Compatible with various fieldbus protocols

We have extensive experience in handling a wide variety of interfaces. We can also handle fieldbus protocols other than those mentioned above.

Please contact us for inquiries about fieldbus protocols.

03 Motor control expert with 40 years of experience

Annual shipments of over 100,000 servo drivers

Leave the development and manufacturing of servo drivers to TIETECH

TIETECH was founded in 1975 to promote automation in the FA industry.

Since then, we have contributed to the automation of factories in Japan and overseas, mainly with robot controllers and drivers.

Thanks to our trust and proven track record based on our technical capabilities, we were able to sell over 100,000 drivers a year.

Development Results

| 1975 | – Start of production and sale of controller for injection moulding extraction machine. |

|---|---|

| 1983 | – Start of production and sale of controller for compact injection moulding machine. – Start of production and sale of 3-axis CNC system. |

| 1984 | – Start of production and sale of 6-axis articulated robot controller. |

| 1999 | – Starts of production and sale of super video phone system “V-PHONET”. |

| 2000 | – Development and mass production of welding robot controller. |

| 2001 | – Development and mass production of control board for dental chair. |

| 2002 | – Development and mass production of gas cutoff control device. – Development and mass production of hydraulic solenoid controller. |

| 2003 | – Development and mass production of thermal displacement amplifier. |

| 2004 | – Development and mass production of control unit for large commercial refrigerator. – Development and mass production of remote maintenance unit with mobile module. |

| 2006 | – Development and mass production of gas flow monitoring and control equipment. – Development of mannequin robot. |

| 2008 | – Development and sale of PCI motion control. |

| 2009 | – Development, mass production and sale of FDD-USB conversion unit. |

| 2010 | – Development and mass production of new power supply board for amusement equipment. – Mass production of driver for stepping motor. – Start of sale of multi-axis integrated controller. |

| 2012 | – Development and mass production of current AMP type servo driver. – Development of robot controller. – Development of general-purpose small pendant. |

| 2015 | – Start of sale of servo driver integrated bot controller compatible with SCARA robots. |

| 2017 | – Development of multi-axis servo driver with integrated power supply. – Development of ultra compact servo driver. |

| 2018 | – Development of large capacity servo driver. – Development of general-purpose robot controller. |

| 2019 | – Development of large screen customized pendant. |

| 2021 | – Development of servo driver for China market. |

| 2022 | – Development of multi-axis integrated servo driver. |

Development Environment

| Hardware | |

|---|---|

| Supported processor | ARM processor – Runesas, TI, ST, NXP(Freescale), Marvell, Toshiba, etc. – Renesas SH series – Various MCUs |

| FPGA | – LATTICE : MachXO, LatticeXP2 – XILINX : SPARTAN – ALTERA : Cyclone, MAX |

| High-speed memory and various interfaces | – DDR2, DDR3, PCI-e, USB3.0 – EtherCAT, PROFINET, EtherNET/IP, Modbus-TCP/RTU, CANopen etc. – Bluetoothe(BLE), WiFi, NFC |

| CAD | – Circuit design : CADVANCE, OrCAD – Board design : CR-8000, CADVANCE, Altium/td> |

| Software | |

| Development technology | – Robot controller, sequencer, motion, servo control – Scara robot control, Parallel link Robot control – Teaching screen, operation |

| Scope of work | – Requirement analysis, specification writing, basic design, coding – Test design, integration testing, support |

Manufacturing Site

- SMT line / various inspection equipment

- A full line of high-precision, high-performance SMT mounting equipment. We can improve productivity and quality.

- DIP line / inspection line

- We pursue flexibility to respond to production fluctuations and shortened lead times. High quality, low cost, and short delivery times are realized through a functional production system.

- Production line

- Stable quality and efficient production are achieved by using the know-how cultivated through the assembly of various products such as control panels, controller units, and small pendants.

- Printing condition inspection equipment

- Automatic hot melt coating machine

- Modular placement machine

- 3D visual inspection equipment

- Selective flow soldering machine